Sand blasting

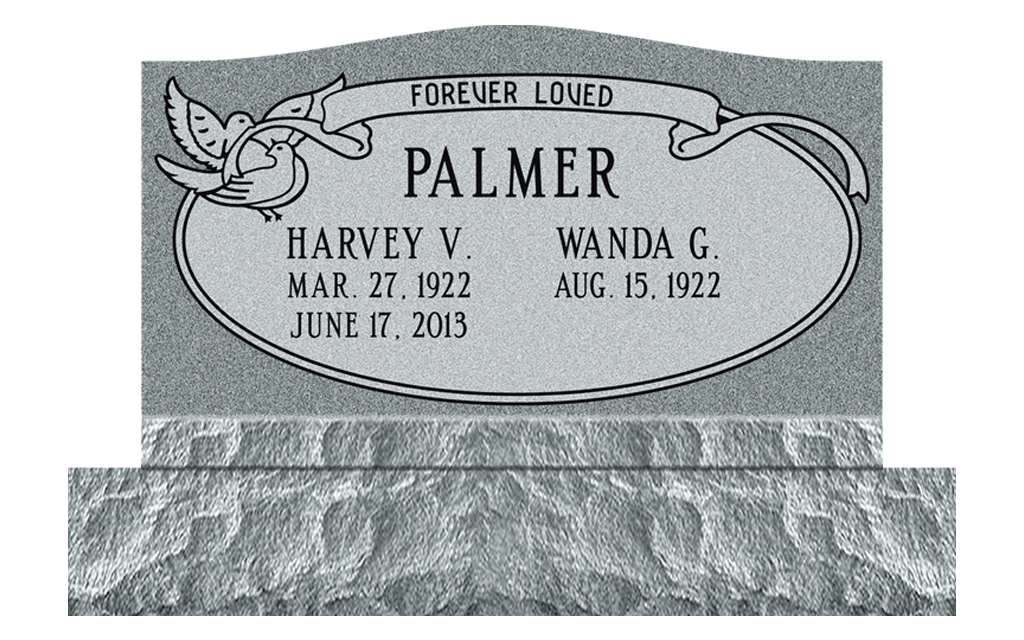

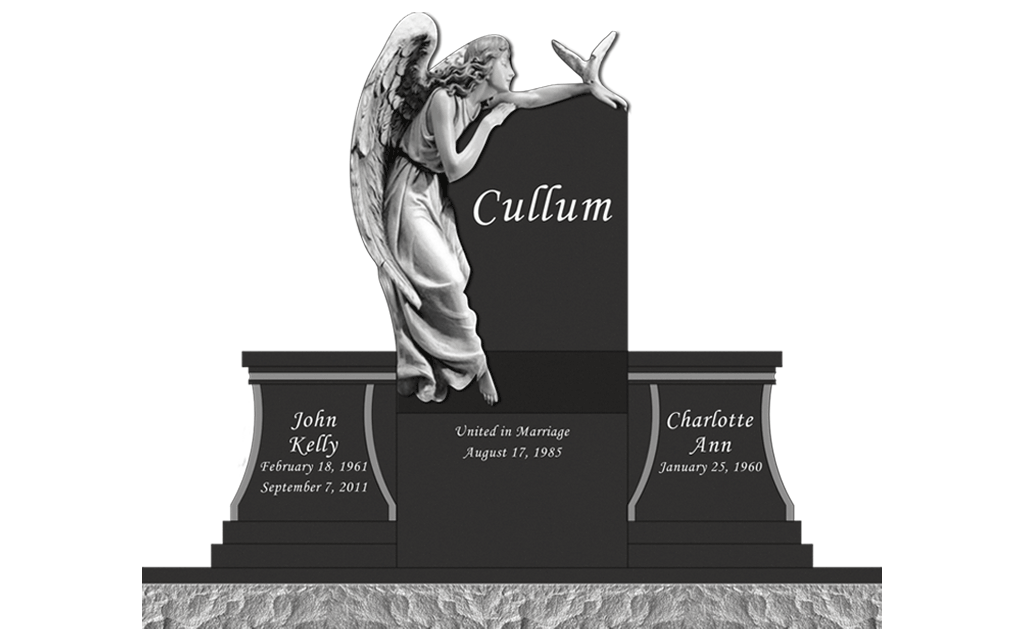

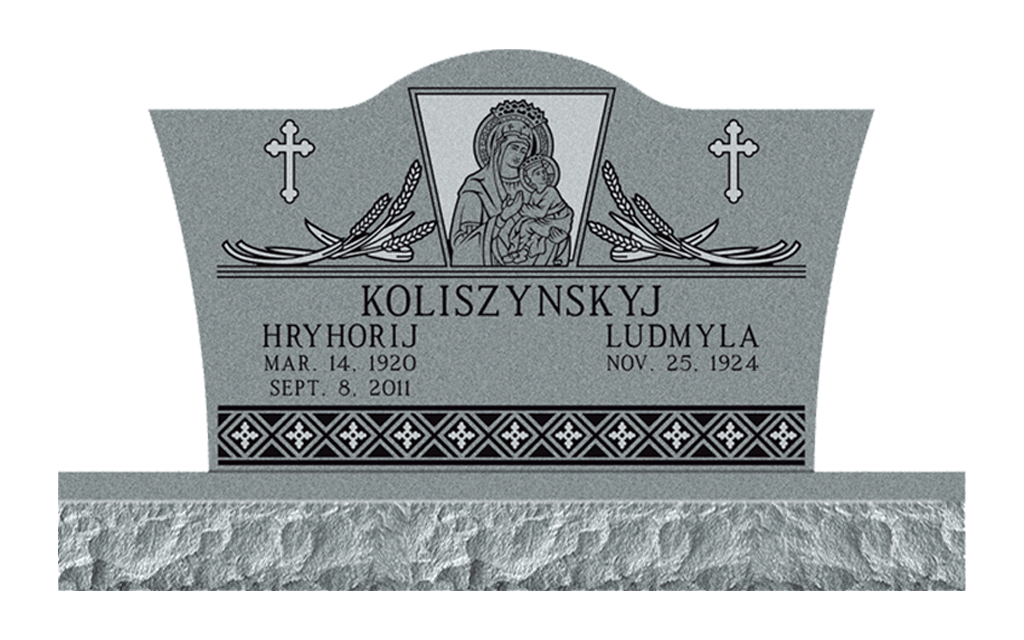

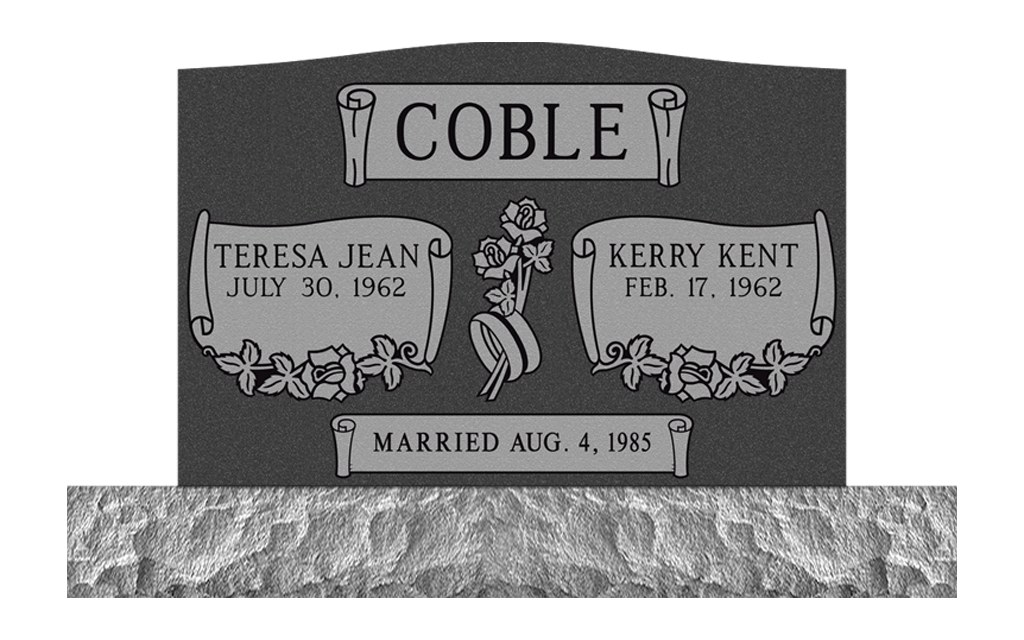

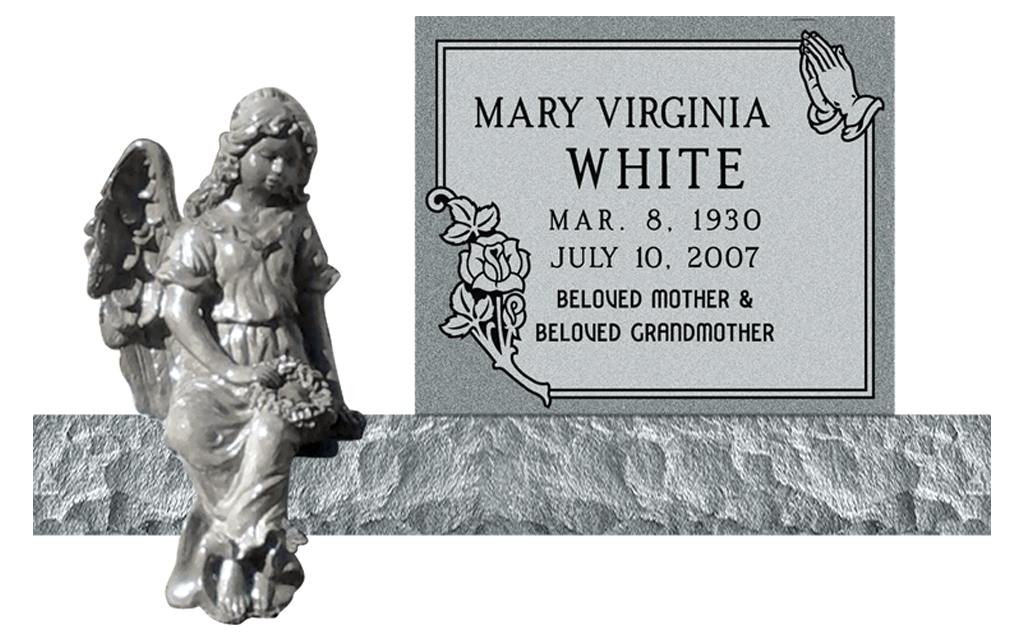

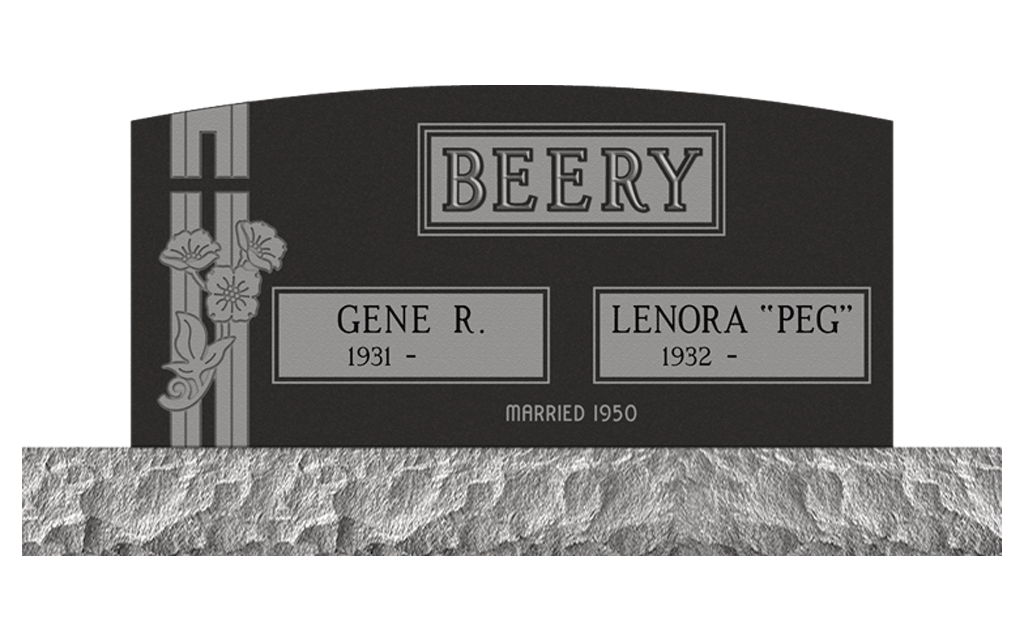

Granite that is not polished and dry will be light gray color, no matter what the type of stone it is. The actual characteristics of the stone is visible only when the granite is polished using fine abrasive polishing pads and over 14 steps starting with a coarse grit to a fine grit. Sand Blasting is a process of removing polish out of the granite surface and exposing the contrast between the polished and unpolished surface. The difference in the depth provides the various effects on the monument.

Designs to be sand blasted are laid out of a CAD software that will product machine readable files that are fed in advanced CNC machines. The CNC machines cut the required layout on a multiple layered rubber stencil. The areas the need to be sandblasting (where the lettering and artwork are required) are peeled off of the stencil.

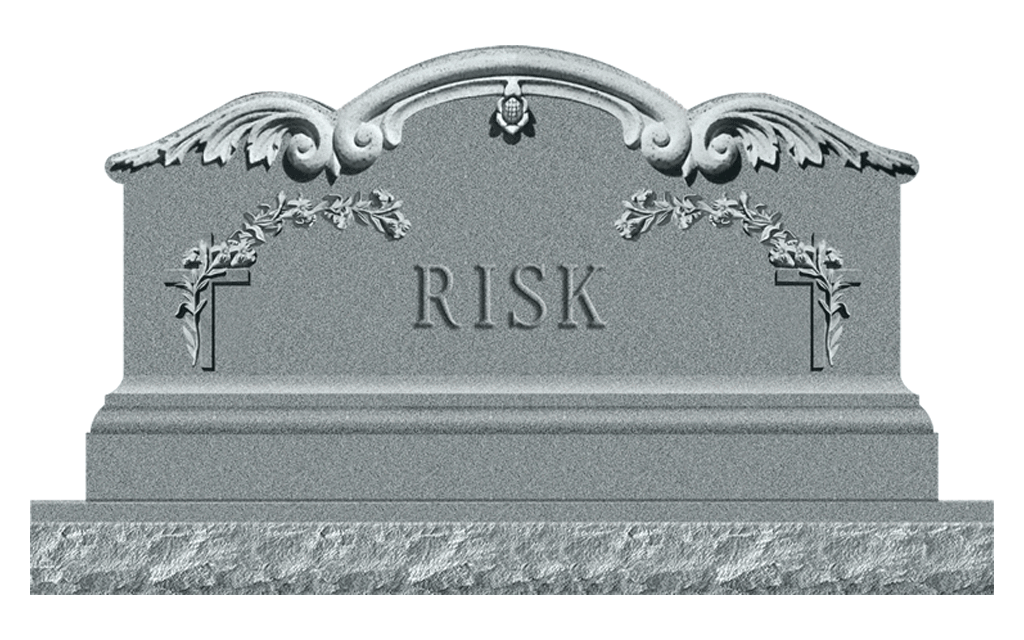

Prepared stencil is then mounted on to the blank headstone. Headstone with the stencil is then loaded into an automated CNC controlled sand blaster. A narrow nozzle with high pressure air mixed with aluminum oxide points the jet towards the monument. This creates an abrasive effect on the granite memorial at high forces. The number of passes that it takes to sand blast depends on the depth required.

For fine processing like shape caring (3Dimension carving of artwork like roses) the monument is then places in a shape carving sand blaster. Fine nozzles with about 1/8" diameter is used to carve out finer details.